How Electrical Relays Ensure Safe Operations

Electrical relays are the unsung heroes of countless systems across industries. For electrical engineers, technicians, and industry professionals, electrical relays ensure safe operations in multiple ways. In our guide, we’ll explain their importance to safety, the common types of electrical relays and their uses, and more.

The Basics of Electrical Relays

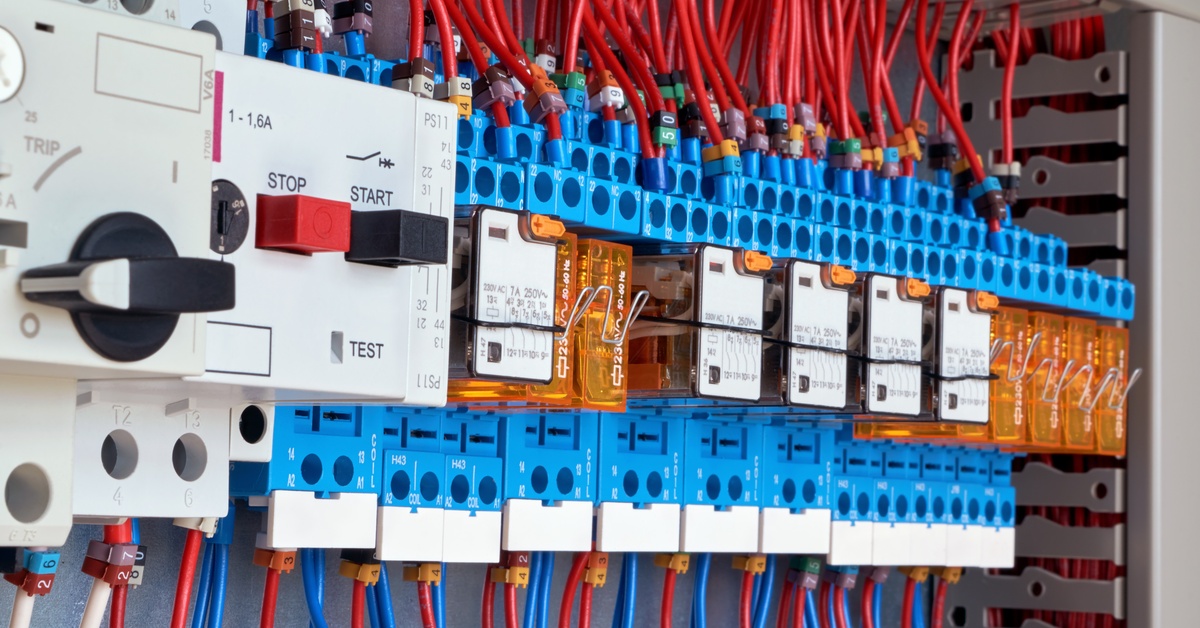

First, what is an electrical relay, and what is its job? An electrical relay is a switch controlled by an electrical signal, automating circuit control without human interaction. It uses a low-power input to trigger a larger output current, making it ideal for safely managing high-voltage environments.

Relays operate on electromagnetism; when energized, the input circuit creates a magnetic field that activates the output circuit by closing a contact. This design isolates high-voltage systems from low-voltage controls, reducing hazards and improving system integrity.

Why Relays Are Crucial for Safety

Electrical relays ensure safe operations by providing reliability and control in electrical systems. They protect equipment by shutting off circuits during faults or overcurrent scenarios, such as preventing an overloaded motor from overheating or causing fire hazards in industrial setups. Relays also enhance worker safety by allowing low-voltage controls to manage high-voltage tasks remotely, eliminating the need for direct interaction with dangerous circuits.

Common Types of Electrical Relays

While all electrical relays serve the same purpose, there are different types for distinct work. Some common types of electrical relays include electromechanical relays, solid-state relays, and time-delay relays.

Electromechanical Relays (EMRs)

Electromechanical relays are one of the most common types, featuring physical contacts and a simple design. They are reliable and well-suited for straightforward tasks, such as controlling heating elements or motors.

Solid-State Relays (SSRs)

Solid-state relays rely on electronic components instead of moving parts, making them ideal for environments that require rapid switching and durability. Without moving contacts, SSRs are less prone to wear and tear, making them perfect for long-term, high-frequency operations.

Time Delay Relays

Time delay relays add an extra layer of functionality by introducing a programmable delay before activation or deactivation. These relays are prevalent in sequential control systems. For example, a time delay relay might ensure that equipment shuts down only after completing its cycle, preventing abrupt interruptions.

Safety Relays

Safety relays are specifically for vital safety applications. They monitor conditions like emergency stop buttons, door interlocks, or light curtains and respond quickly to shut down hazardous systems. These relays play a vital role in ensuring compliance with safety standards.

Standards and Regulations for Safe Relay Usage

Electrical relays must meet strict standards set by organizations like the IEC and UL to ensure reliability and safety. Certified relays are important, particularly in industrial settings where they must meet insulation and temperature-resistant requirements to operate under demanding conditions. As a relays and contactors supplier, we ensure that all our products meet the highest standards and qualifications for industrial work.

Find Reliable Electrical Relays at Tanooga

Electrical relays are essential for secure and efficient operations in both industrial and residential settings. They automate control, isolate circuits, and respond to irregular conditions, protecting equipment, operations, and people.

If you need to find electrical relays for work, Tanooga is here to help. We offer a wide selection of relays for various applications. Browse our inventory or contact our staff today.